Which Solar Panels Are The Best?

Label:

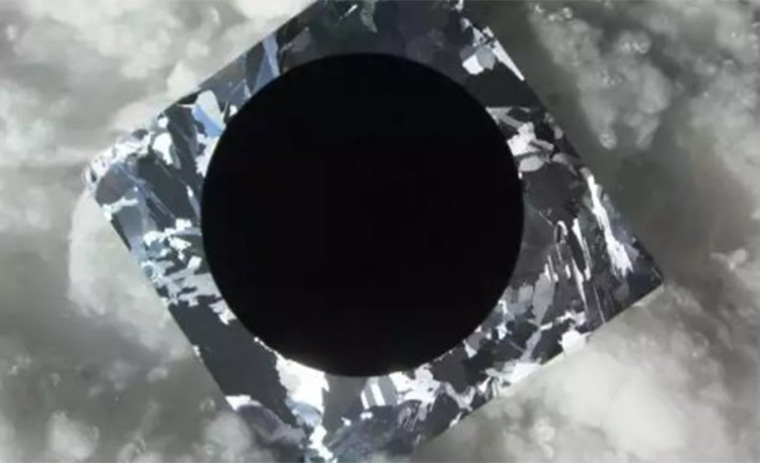

Solar Panel

Solar panels, as the name implies, convert sunlight into electrical energy. The more sunlight is absorbed, the more electrons can be produced. The most common material for solar panels is silicon (Si), but silicon itself has about 40% reflection of visible light, which means that 40% of the sunlight that is irradiated onto the silicon surface is directly bounced back and cannot be used. The solar panel emits an anti-reflective layer on the silicon surface to reduce the loss of reflection. The lower the reflectivity, the more light is absorbed by the silicon and the more electrical energy is converted.

Since the light should be absorbed, the surface of the solar panel should be as dark as possible, but the solar panels that everyone thinks are dark blue. This is because the anti-reflection layer of the solar panel cannot completely reduce the reflectivity of blue light. Close to 0, because the reflectivity of blue light is higher than that of other colors, it looks dark blue. Therefore, in order to make full use of sunlight, it is necessary to make the surface of the material hardly reflect, only absorb, and the color will of course be black. "Black" silicon is the goal of engineers. In general, to make an anti-reflection layer, it is necessary to etch the silicon surface into a micron or even a nano-like roughness structure. The smaller the structure, the lower the reflectivity will be.

The technology itself is not difficult to achieve, black silicon has long been developed, but black silicon has a very serious problem: when the solar panel shines, the photons are converted into electrons, and the electrons are transferred. The loss is very large. The surface of silicon is usually the main way to lose electrons. Although black silicon can absorb a lot of light, it can be converted into many electrons, but it is because the small nanostructure on the surface of black silicon makes the surface area increase greatly. More electrons are lost on the surface. The Aalto University in Finland and the Polytechnic University of Catalonia have discovered the use of Atomic Layer Deposition (ALD) to coat alumina on the black silicon surface as a passivation layer. It can effectively suppress the loss of electrons on the surface and increase the efficiency of black silicon solar panels to 22.1%. This research was published in Nature Nanotechnology.

The difference between black silicon and traditional deep blue solar panels is that traditional silicon solar panels use lye (usually alkali metal hydroxide) to etch the silicon surface into a pyramid-like micro-structure; A nano-scale small structure is etched on the surface by reactive ion etching (RIE). The structure etched by the lye is larger, the anti-reflection effect is relatively poor, and the silicon lost during the etching process is more; while the reactive ion etching not only has a small structure, but also less silicon is lost, and the anti-reflection effect is also compared. it is good.

Anti-reflection has two main points, one is wide band and the other is wide angle. The spectrum of sunlight from ultraviolet light to visible light to infrared light can effectively use all the light if the reflectance of this whole band is low. As mentioned above, the principle of anti-reflection is that the finer the surface structure Small, the lower the reflectivity and the wider the band, which is one of the reasons why black silicon can be so "black". The black silicon in this study has a reflectance of less than 1% in the visible light range. It can be said that almost all The light is sucked in; the other focus of anti-reflection is the wide angle, because the sun does not always shine from the top, from sunrise to sunset, the sun is almost angled, the vast majority of materials, As the incident angle becomes larger, the reflectance also rises sharply, causing the solar current to drop. The black silicon cell in this study has a current that is only 1% less than normal incidence at an incident angle of 60 degrees, and the efficiency is hardly affected by the angle of the sun. Professor Hele Savin, who led the study, said: "This is especially important for us in Northern Europe. Most of the time the sun is incident at very low angles."

The study they published boosted the efficiency of black silicon solar panels from 18.2% to 22.1%. Don't underestimate the 3.9% gap. In the solar panel field, a 1% increase is big news, let alone 3.9%. . At present, black silicon solar panels have not yet been commercialized, so this dark black solar panel is not seen on the road. Researcher Pablo Ortega who participated in the research said: "About three or four years, we can see black silicon. Solar panels appear on the market and are used in industry."